{tab GEOTUB®|blue}

GEOTUB® - The 1st plastic formwork for round columns

GEOTUB® - The 1st plastic formwork for round columns

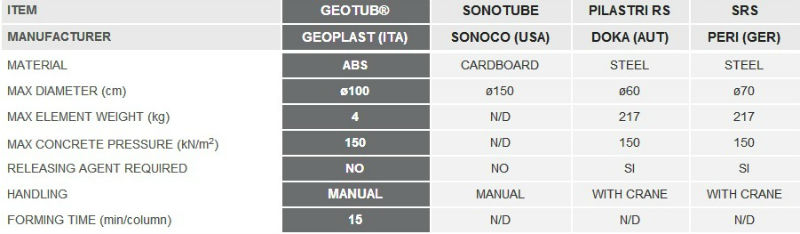

GEOTUB® is the first reusable plastic formwork for round concrete columns. A new concept versus disposable formworks made of cardboard or other material: stripping is made quick and easy since no releasing agents are required, and it can be used over and over again, column after column.

GEOTUB® is a complete formwork system for circular columns in any building type.

The forms can be carried by hand by a single person without the aid of a crane or of heavy lifting equipment.

Geotub is a reusable formwork.

The smooth finish of the Geotub forms leaves a very good concrete finish. As the plastic surface does not require releasing agents, it leaves no blemishes or discolouring on the concrete.

After the pour clean the forwork from any concrete with a water jet, and after dismantling just cleanse the forming face with water.

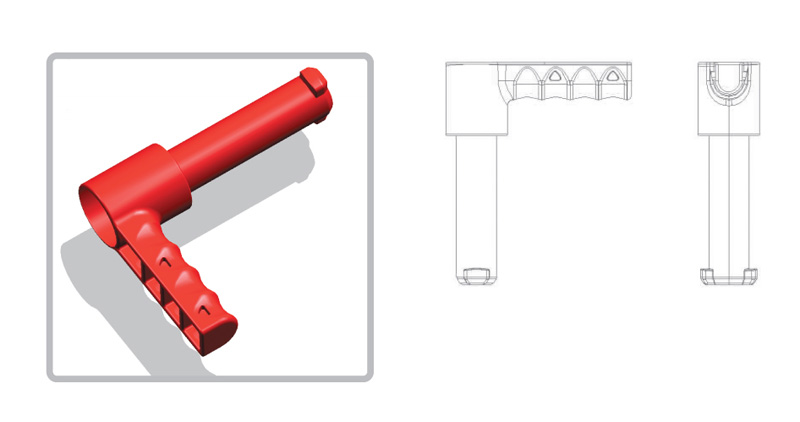

The forming parts are locked together by high-strength nylon fixing handles.

GEOTUB® - Technical and Packaging Data

GEOTUB® - Technical and Packaging Data

GEOTUB® is a high impact strength ABS plastic formwork, UV-stable and chemicals-resistant.

{tab ACCESSORIES|blue}

GEOTUB® ACCESSORY: HANDLE The formwork erection and stripping after the pour are easy and fast operations thanks to the special handles that lock the forms with a simple 90 degree turn.

The formwork erection and stripping after the pour are easy and fast operations thanks to the special handles that lock the forms with a simple 90 degree turn.

GEOTUB is a reusable formwork.

The single forming elements are joined using the standard high-strength nylon fastening handles.

All fixing handles required by the form must be used to ensure the specified strength of the formwork.

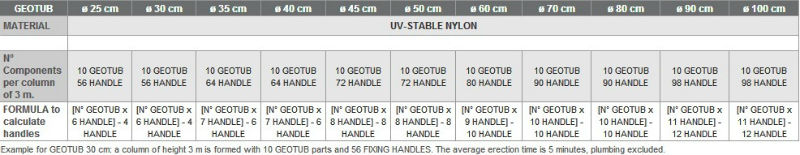

GEOTUB® ACCESSORY: FIXING HANDLE CHART

{tab APPLICATIONS|blue}

GEOTUB® APPLICATIONS: Circular columns for residential and industrial buildings

GEOTUB® is a complete system designed to form round columns for all types of building.

GEOTUB® is a complete system designed to form round columns for all types of building.

TheGeotub® forms are very light and can be moved by a single person without the aid of a crane or of lifting equipment.

Geotub is a reusable formwork.

The Geotub® formwork does not require any releasing agent and is used with all standard concrete pumps and form vibrators.

THE ADVANTAGES OF GEOTUB:

» modular;

» light weight;

» fast to erect and plumb;

» easy to store;

» reusable;

» does not require releasing agents;

» excellent concrete finish.

{tab COMPARISON|blue}

GEOTUB®: Comparison with similar system

GEOTUB®: TECHNICAL advantages

REUSABLE

REUSABLE

GEOTUB® is cost-competitive as it can be used for an average of 100 pours. As concrete does not stick to plastic, cleaning of the formworks is done using just some water: the use of detergents and stripping agents is not necessary.

FAST ERECTION AND DISMANTLING

Setting-up the formwork and stripping after pouring are easy and fast operations, thanks to the special handles that lock with a simple 90 degree turn.

MODULAR

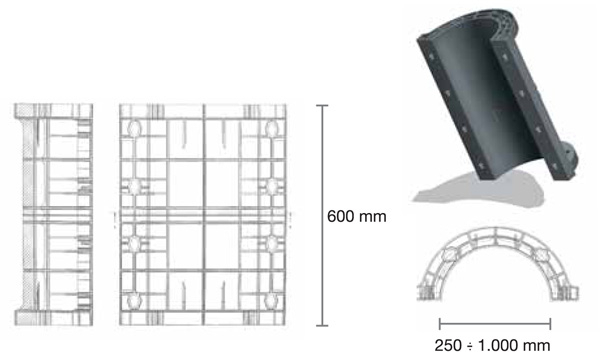

GEOTUB® is a modular element with a height of 60 cm: it does not need to be cut to length as only the amount of elements required for the pour is used.

STORAGE

GEOTUB® can be completely disassembled and does not need to be stored in a dry environment.

ON SITE HANDLING

Thanks to their small size and weight, the elements can be easily handled in the construction site, and can be easily assembled where required.

RESULT

The surface of columns poured with GEOTUB® can be left in sight without any further rendering.

{tab INSTALLATION|blue}

GEOTUB®: Installation

GEOTUB® is a formwork made of high impact resistant ABS plastic, UV-stable and resistant to most chemicals.

GEOTUB® is a formwork made of high impact resistant ABS plastic, UV-stable and resistant to most chemicals.

TheGeotub® forms are very light and can be moved by a single person without the aid of a crane or of lifting equipment.

Geotub is a reusable formwork.

The inner surface of the formwork is very smooth, leaving a very good concrete finish. As the plastic surface does not require releasing agents, it's possible to avoid blemishes and discolouring of the concrete. After use the forms are simply cleansed with a water.

The single forming elements are joined using the standard high-strength nylon fastening handles.

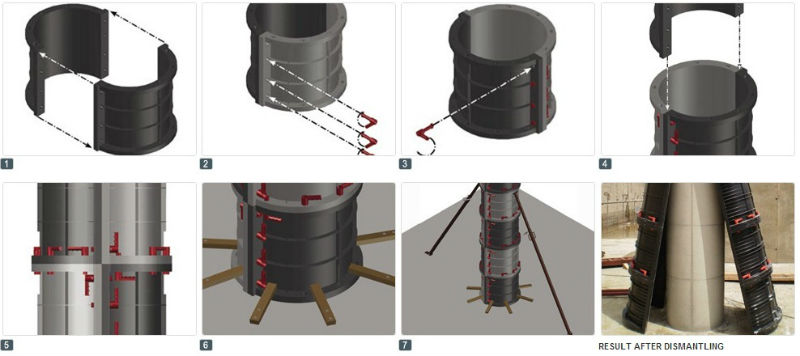

Follow these steps for a correct and fast erection of the Geotub® formwork:

1. Place two Geotub® parts so that the two joining flanges meet, thus creating a circular form;

2. insert the high-strength nylon fixing handles from the bottom of the form up. Turn each handle by 90° to lock the parts;

3. the handles at each end of the part junction flange are turned by 90° inwards;

4. The locking of the handles is made easier if these are inserted alternately from the two sides of the form joining flange;

5. The handle grip is indifferently oriented upward or downward, preferrably without overlapping any two of them. (fig. 5 shows the ideal handle position). Continue coupling the Geotub® modular elements, interlocking them vertically and horizontally, until the desired formwork height has reached.

The full locking of all the handles guarantees the specified strength of the formwork and furthermore ensures the correct alignment of every part of the formwork;

6. Once the Geotub® column formwork is assembled, fix it to the ground with wood;

7. The plumb of Geotub® is easy and fast: two standard props are enough to stabilise the form.

All fixing handles required by the form must be used to ensure the specified strength of the formwork..

Download the GEOTUB® handbook

{tab LITERATURE|blue}

GEOTUB®: Available literature

{tab VIDEO_GALLERY|blue}

{/tabs}